Description

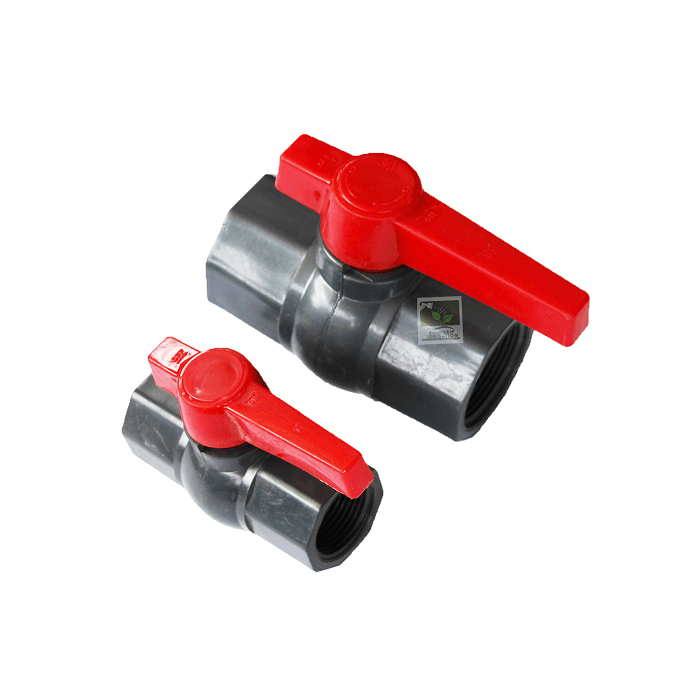

Ball valve water controller

This is an irrigation valve which controls water by means of rotating the ball with a hole through its center.

When the ball is rotated so that the hole is not aligned, the flow is completely shut off. Ball valves are used primarily as isolation valves. They tend to be very reliable and trouble-free and they tend to require more effort to turn on and off than other valves but for the larger size pipes, butterfly valves are usually used rather than ball valves.

Majority of the ball valves have arrows indicating the direction of movement i.e. on and off shut offs. .

Ball valve sizes

The available sizes are:

- 20 millimeters nominal diameter or ½ inch.

- 25 millimeters nominal diameter or ¾ inch

- 32 millimeters nominal diameter or 1 inch

- 40 millimeters nominal diameter or 1 ¼ inches

- 50 millimeters nominal diameter or 1 ½ inches

- 63 millimeters nominal diameter or 2 inches

- 75 millimeters nominal diameter or 2 ½ inches

- 90 millimeters nominal diameter or 3 inches

How to connect ball valves to the irrigation systems

These valves may come of different forms depending with the type of the fixing ends. The fixing ends are either plain, internally or externally threaded ends. So it is very important to consider the type of the pipes or irrigation tool you are going to use.

Choose the valve according to the size of your system related to the sizes listed above. When internal threaded ball valve is considered, take the male adaptors or PVC valve sockets to fix to the ends. Tighten the ball valve to avoid leakages.

Irrigation ball valve water controller is a hollow plastic with a valve which uses a hollow, perforated and pivoting ball to controls the flow of water through it.

These types of plastic ball valves water controller can grant high flow coefficients compared to other types of valves.

How ball valve water controller works

Ball valves controllers opens by turning a handle attached to a ball inside the valve. The ball has a hole through the middle, so that when the port is in line with both ends of the valve, flow will occur.

The ball valve, which can make a quarter turn (90°) around the turning point is the on/off control of the ball valve. More so

Ball valves, which need a little rotating force and turn a quarter, can be closed tightly. The completely equal lumen provides a littler-resistance green passage

Main Operational features.

-

High control volume capacity:

- The unrestricted flow passage in fully open position provides high Control combined with relatively small overall dimensions and light weight compared to the same size globe valves: a given size ball valve can grant a control volume coefficient even three times greater than a same size globe valve. This ensures a smaller and lighter valve, a smaller and lighter actuator, smaller pipeline supports and overall a money-saving application compared to standard linear valve solutions.

- High Sensitivity Control rate: have spring loaded seats design that assures scraping action and continuous contact between seat and ball: dirty fluids do not stick and jam on the ball surface.

- Compact design: Body construction, special design for stem and actuator connections eliminate free-play (backlash) and assure great resistance even against piping forces.

- Fast operating time: Quarter turn design allows using fast actuating devices which can perform emergency operation in a few second to improve the safety of the plant.

- Low emission stem packing: Special design of stem sealing assures low emission performance to meet Fugitive Emission requirements.

- High system design capacity :The unrestricted flow passage in fully open position provides high capacity combined with relatively small overall dimensions and light weight compared to the same size globe valves: a given size ball valve can grant a Cv coefficient even three times greater than a same size globe valve.

Advantages of ball valves.

-

Fluid resistance is zero

The diameter of channel equals to the inner diameter of pipe, the local resistance loss also equals to the friction resistance of the pipe, and so the full port Model, also called full flow type, is the Ball valve with the min fluid resistance. In the rocket launching and test system, it required the resistance of the pipe the less the better. There are two ways to reduce the resistance of the system.

-

Easy and rapid open-close operation

under normal circumstances, ball valves can finish the open-close operation easily and rapidly by quarter turn (90°).

-

Outstanding seal property

- Generally, it’s easy to make sure the tightness of the soft seal, what’s more, the requirement of the machining accuracy and surface roughness of the seal does not high.

Long life-span

Due to the good self-lubricating of PTFE, small friction with the ball, the advancement of ball processing technology, reducing of roughness, the ball valve’s life-span has been greatly improved.

-

Minimal accident

Built-in stem structure can remove the potential accidents of the fly-out of the stem, caused by the loosen of packing under the fluid pressure.

Design specifications.

- They are of plastics of high density.

- General discharge rate of ball valves should range between 10000 litres/hr to 30000litres/hr depending on size used