DRIP IRRIGATION SYSTEM DESIGN

Description

Drip irrigation system design is a method of irrigation where water is applied slowly and frequently, directly into the vicinity of the root zone of the crop wetting only a very limited fraction of total surface area and depth of the soil. Water is applied close to plants so that only part of the soil in which the roots grow is wetted, unlike other systems of irrigation, which involves wetting the whole soil profile. With drip irrigation water, applications are more frequent than with other methods and this provides a very favorable high moisture level in the soil in which plants can flourish.

Drip Irrigation system is based on two main fundamental concepts of irrigating only the root zone of the crop rather than the entire land surface and also maintaining the water content in the root zone at near optimum levels

Drip irrigation system is accomplished by use of pressures ranging from 15 to 200 kPa (1.5 to 20 m head of water) to drip water one-drop-at-a-time onto the land or into the root zone and also to spraying water as a fine mist over portions of the land surface.

Factors to consider when selecting the drip irrigation system design.

Drip irrigation system is one of the cheapest and easiest ways of irrigation a farmer should prefer. While selecting this type of irrigation system the following factors should be considered.

-

Types of crops

Drip irrigation system is most suitable for row crops including vegetables, fruits, tree and vine crops where one or more emitters can be provided for each plant. Generally, only high value crops are considered because of the high capital costs of installing a drip system.

-

Nature of the land.

Drip irrigation system is adaptable to any farmable slope. Normally the crop would be planted along contour lines and the water supply pipes would be laid along the contour also. This is done to minimize changes in emitter discharge as a result of land elevation changes.

-

Suitable soils

Drip irrigation system is suitable for most soils. On clay soils water must be applied slowly to avoid surface water ponding and runoff. On sandy soils higher emitter discharge rates will be considered to ensure adequate lateral wetting of the soil.

-

Suitable irrigation water

Drip irrigation system requires water that is clean and free of sediments, algae, fertilizer deposits and undissolved chemical particles. This is because all emitters have very small waterways with diameter ranging from 0.2 to 2mm, which can become blocked if the water in dirty. Dripping water to individual plants also means that the method can be very efficient in water use. For this reason, it is most suitable when water is scarce.

Components of Drip irrigation system design.

Drip irrigation system is comprised of the following basic elements:

Control head (Central Control).

This comprises of valves, discharge, and pressure meters. It provides a means for Control and regulation of discharges, and pressures, including non-return valves and air vents. It also has an automation and control equipment, filters and dissolved fertilizer applicators. Depending on the size of the system, there may be several control heads, each serving an irrigation unit.

The Main pipe

This is generally a rigid pipeline made from HDPE, asbestos cement or concrete. The main pipe is almost always buried and conveys water from the source to the main control points in the field.

The Sub-main pipe

This is a multi-valve pipe distributing irrigation water to the various sub-units within a unit. A sub-unit in this case represents an area which simultaneously receives irrigation water from a single control point and which is being controlled by a valve on the sub-main.

It is made up of rigid black polyethylene pipe which in most cases laid on the ground surface, with a diameter ranging between 32mm to 90mm (1.25” to 3.5”), at a pressure of 4 atm.

When designing the sub main line, it is good to consider several factors which include topography of the land, field geometry, water supply and the uniformity required.

The Auxiliary or Manifold pipe.

This is either a flexible (soft) or rigid pipe of high density polyethylene type, generally 20 to 75 mm diameter, which distributes water between the laterals belonging to a single sub-unit.

The manifold and its lateral are designed and operated as a single unified system which is controlled by a single valve.

Lateral (or Drip line) pipe.

This is basically a flexible (soft) polyethylene or PVC pipe buried or laid on the ground surface and which carries emitters. Its diameter ranges from 12 to 25 mm (0.5 to 1 in) and the pressure rating about 4 atmospheres. A typical trickle system may have up to or more than 10 km/ha of laterals.

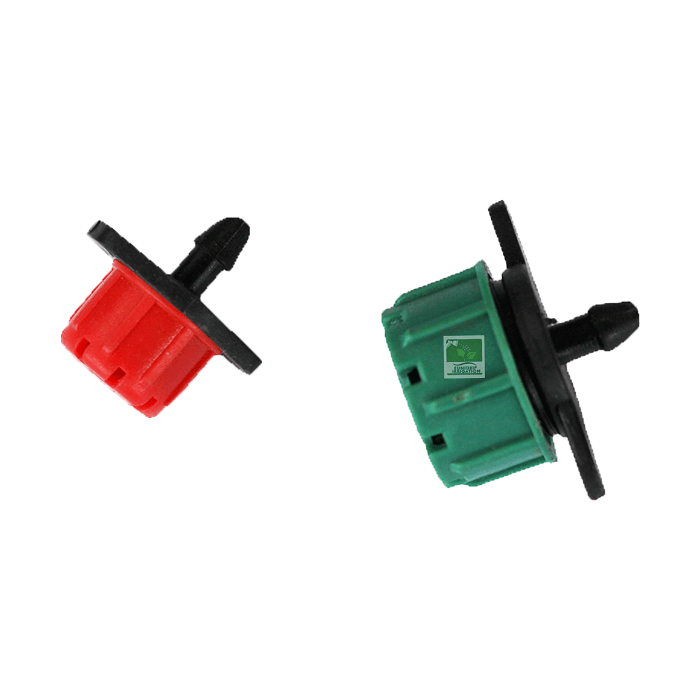

The Emitters.

An emitter is a device or system element which makes the drip irrigation possible by providing irrigation water at low flows and atmospheric pressure. The performance of emitters determines to a large extent the efficiency of the system. Since their number is usually very high (from 2,000 to 20,000 per ha,

In Drip irrigation system, the most suitable emitters used are selected based on the following factors such as low in cost, uniform in structure and operation, simple to manufacture, and install, should be able to maintain low problematic at standard operating pressure (3 to 30 m), and should be able to produce a constant low-rate water supply at varying line pressure change.

The Specification of Emitters used in Drip Irrigation System design.

- There are numerous designed specifications of an optimum emitter used in drip irrigation system:

- It should be available in small increments of discharge on the order of 1 L/h.

- The flow should be controlled within narrow limits as a function of operating pressure to properly balance applied water with crop water use;

- The emitter should be able to resist degradation due to temperature fluctuations and solar radiation.

- The operating pressure should be 2 to 5m (for low pressure) and 8 to 15 (for high pressure).

- The discharge rate of emitters should range between 4 liters per hour (for low rate).4 to 10 liters/hour (for medium discharge), and beyond 15litres per hour for high discharge.

- Should be able to offer flow regime of laminar flow, turbulent or partially turbulent.

The operating principle of Drip irrigation system design.

A drip irrigation system is usually permanent. When remaining in place during more than one season, a system is considered permanent. Thus it can easily be automated. This is very useful when there is little labour force. However, automation requires specialist skills and so this approach is unsuitable if such skills are not available.

With drip irrigation system, water can be applied frequently or every day if there is possibility. This can provide very favorable conditions for crop growth. However, if crops are used to being watered each day they may only develop shallow roots and if the system breaks down, the crop may begin to suffer very quickly.

The wetting patterns of drip irrigation emitters.

Drip irrigation only wets part of the soil root zone. This may be about, low as 30 – 40% % of the volume of soil wetted by the other methods of irrigation. The wetting patterns which develop from dripping water onto the soil depend on discharge and soil type.

Drip irrigation is not a substitute for other proven methods of irrigation. It is just another way of applying water. It is best suited to areas where water quality is marginal, land is steeply sloping or undulating and of poor quality, where water or labour are expensive, or where high value crops require frequent water applications.

Specific problems associated with drip system of irrigation.

As a matter of fact, Drip irrigation system being that it is cheap and easy to install, it is also associated with some of the emerging problems and challenges. These challenges are as mentioned below.

Emitters or drippers clogging effect.

The most serious problem in proper design, operation and maintenance of drip system of irrigation is emitter clogging. The orifices of drip system emitters or drippers are extremely small compared to the once in other systems of irrigation. There is therefore, high potential for emitter clogging by particulate, chemical precipitates, and bacteria. Emitter clogging can have severe impact on crop development because of the careful balance between crop water requirement and emitter discharge built into the design of trickle irrigation systems.

Solutions to problems associated with emitters clogging in drip irrigation system.

Criteria to handle the susceptibility of water supplies to emitter clogging should be developed in order to enable the designer to make decisions about the utility of water supplies that is necessary for drip irrigation. These criteria can help the designer in deciding whether drip irrigation system is the most adaptable system for a particular water supply and what type of filtration and water treatment devices may be required depending on the severity of the potential clogging problem.

-

Use of appropriate filtration system.

Filters should be used to remove undesirable material from the water supply before it enters in the distribution system and creates potential for emitter clogging. Some type of filtration system is required on virtually in any drip system to ensure efficient system operation. Different types of filtration devices are effective in removing different size material from water source. The filter should be sized based on the emitter opening and the type of material to be removed. The most common filtration systems used for trickle irrigation systems Includes media or sand filters, Screen filters and Centrifugal filtration systems.

-

Bacteria Treatment

Drip irrigation distribution systems can be clogged in a very short time by bacteria slime which blocks the distribution system.

High bacteria concentrations require treatment by bactericides, which contains chlorine or other compounds which must remain in contact with the water source long enough to kill off the bacteria. Normally 10 – 30 minutes of contact in a solution with free residual chlorine concentrations of 1 mg/L is adequate.

-

Chemical Treatment

Chemical treatment is required to reduce the potential for precipitation of insoluble salts at the orifice and internal parts of emitters which causes clogging.

These precipitates are commonly caused by the reactions of soluble calcium and bicarbonates in the irrigation water, producing calcium carbonate.

The normal procedure to inhibit this reaction is to control the solution pH by addition of various acids recommended for use.

-

Fertilizer Injection Systems

Drip irrigation system designs are particularly adaptable to fertilizer injection into the distribution system. This is because the water is applied directly to the plant root zone.

This leads to efficiency of fertilizer use, reduced energy and labour costs, and flexibility in field management

However, care must be exercised to prevent the fertilizer from corroding the distribution system components.

It should also be noted that due to water supply, algae growth and bacteria slime problems may occur. These can cause clogging emitters and screen and filter blockage.

-

Operation Procedures of Injection Equipment

The basic principle of operating fertilizer and chemical equipment injection systems is that the material should not be allowed to set in the lines when the system is not operating.

Advantages of drip irrigation system.

Drip irrigation system has got various benefits to the farmer as follows.

- Distribution of water is at the optimum level.

- Minimization of Fertilizer or nutrient loss during application.

- Weeds effect are minimized since there is no water available for them

- Drip irrigation enables the farmer to achieve maximum crop yield.

- High efficiency of Fertilizers usage.

- Drip irrigation ensures minimum operating cost

- Reduction of soil erosion

- High water infiltration rate into the soil

- High seed germination rate

- We can use recycled water safely.

- We can irrigate water in irregular shaped lands.

- low energy operation rate

Disadvantages of drip irrigation systems.

- Initial cost of operation is relatively high especially for poor farmers.

- Clogging effect is a very disgusting issue in drip systems of irrigation.