Description

HOSE REEL SPRINKLER IRRIGATION MACHINE.

Hose reel sprinkler irrigation movable machines are installed on “traveling” carts, with a water hose attached. Moreover, the carts can be positioned wherever necessary, as long as they remain connected to a water source.

They are commonly used in irregular-shaped areas; difficult-to-reach areas and fields that cannot be otherwise irrigated because of ditches, power lines, trees, buildings, etc.

Components of hose reel irrigation system.

It’s composed of the following parts.

Polyethylene hose:

However, different models, differing in diameter from 32mm to 150mm, PET hose remarkably modified in elastic characteristics, resistance to traction, granting also have bigger flow rates: all this make them better usable on any kind of soil.

Hydraulic systems:

Almost all new models use systems to grant bigger comfort during use, with assembly of hydraulic controls applied to rotation, supporting legs and other functions. These applications enable an easy use also for an operator only, with reduced labour intervention in exercise and change of position.

Rewinding systems:

The rewinding system is the reel engine of hose-reel irrigation machines. It is the most studied and renewed mechanical-hydraulic apparatus of these machines. From this renewed system depends the even distribution of water, the reduction of losses of pressure, the rewinding speed adjusting of sprinkler and booms, with the precise management of rain height. The new rewinding systems are determinant for the reduction of energy costs as regards the old models.

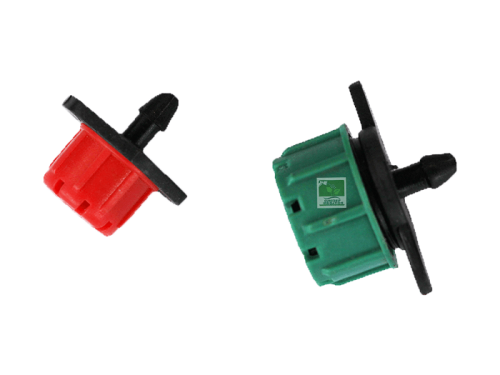

Sprinklers:

The sprinklers used on hose-reel irrigation machines had oscillating arm quick or slow return, having performances with throws varying from 30m to 75 m, ensuring an excellent water breaking. The change of many types of nozzles enables the farmer to choose the most suitable water breaking for his field and cultivation. Recent tests made in some horticultural farms showed the better validity of sprinklers with adjustable speed: the advantage of these sprinklers is the even distribution capacity and uniformity in output, as the advancing is continuous and constant.

Spraying boom:

The introduction and perfecting of spraying booms, as an alternative to sprinklers, determined a high improvement in even distribution of water on cultivation. This equipment enable the use of hose-reel irrigation machines also on delicate cultivation as vegetables and, thanks to use of atomizers and sprayers, they work at very low pressure with an energy saving until 50% as regards the use of sprinklers. The booms, manufactured in galvanized steel or aluminum, grant cross-coverings until 50 meter and over, with excellent evenness and fine water breakages

Control and management panels:

They are most technological and innovative apparatus of hose-reel sprinkler irrigation machines.. The panels, functioning at low voltage (12 Volt) and fed by batteries and solar panels, offer measuring of unwound hose and meters of hose to be rewound; control of flow rate; possibility to program work speed; possibility to program the total time needed for irrigation.

Factors determining base pressure exerted by hose reel machine.

- Topography of the area under operation.

- The gun cart nozzle size.

- The wetted radius.

The movements of spraying gun depend on:

- Area covered by the machine with respect to nozzle diameter.

- Base pressure exerted.

- The spraying gun angle.

The design specification of Hose Reel sprinkler irrigation System.

- The machine can cover an area of 40 meters by 300 metres through a single 180 degrees turn.

- The hose reel gun has a typical nozzle diameter of 24 inches.

- The flow rate or water discharge rate is about 1.14 cubic meters to 1.51 cubic meters.

- The application efficiency of the discharge nozzle is about 70 to 76%.

- The operating pressure of hose reel is about 0.28 MPa to 0.50 Mpa.

- The machine covers wetted diameter of 30 meters to 45 meters.

- The machine can saves water at a rate of 30% as compared to other systems of irrigation.

Advantages of hose reel sprinkler irrigation system

- The hose traveler can be moved in a shorter length of time because there is no hose to reel in and no cable to unwind.

- Pull traveler will require slightly more pressure to operate at the same time and hose length because the friction loss through the hose and drive mechanism is usually greater.

Disadvantage of hose reel sprinkler irrigation machine power.

- Uses a large sprinkler that requires a relatively high operating pressure.

- The machine requires more horsepower to operate and thus more energy consumption

- Labor requirements for traveling gun systems are considerably higher than other system of irrigation.

![Shade net[Net house construction ] insect net For sale in Kenya](https://onlineshop.eunidripirrigationsystems.com/wp-content/uploads/2019/06/20200331_144024-scaled-281x375.jpg)